Designing with Yardley Inserts

Cored or machined holes should be the correct size for the insert used. If the hole is too large, there is a reduction in stripping torque and pull-out force. For optimum performance, the boss diameter should be twice that of the insert diameter. A larger boss diameter increases the stripping torque. Please consult our engineering department for specific recommendations on your applications.

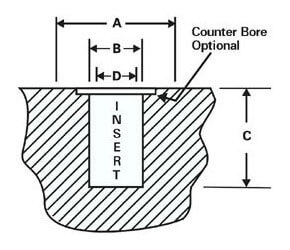

A – Boss Diameter = 2 x insert diameter

B – Insert Diameter

C – Hole Depth = 1.25 x insert length

D – Starting Hole Size – see recommendations for each individual insert type and size