Yardley, PA — Threaded metal insert fastener manufacturer, Yardley Inserts LLC, has come to find the applications which call for the company’s fasteners can sometimes tell the story of the company’s products best.

Yardley, PA — Threaded metal insert fastener manufacturer, Yardley Inserts LLC, has come to find the applications which call for the company’s fasteners can sometimes tell the story of the company’s products best.

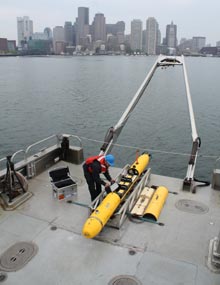

Recently, Yardley began supplying Bluefin Robotics, a leading autonomous underwater vehicle (AUV) manufacturer located in Cambridge, MA with stainless steel threaded inserts for use in unmanned submarines designed for underwater surveying and research.

“The list of applications our fasteners are found in is extensive and broad,” said Tim Bailey, President at Yardley Inserts. “Our relationship as a supplier to Bluefin is a classic example of an application telling the story of our products more effectively than the product specifications ever could.”

Bluefin, who is a leader in underwater vehicles designed for military, commercial, and archaeological exploration and research sought a fastening solution for specific structural plastic components found in the company’s AUVs.

“The specifications called for a threaded insert for fastening plastic structural components together,” said Mike Szegedi, Manufacturing Engineer at Bluefin. “The inserts needed to provide enough strength to prevent the fastened components from pulling apart under any stress.”

Bluefin engineers selected Yardley as a potential suppler when an initial online search for a solution lead to threaded metal insert specifications on Yardley’s website.

“We were able to find a viable solution through Yardley’s website,” said Szegedi. “Yardley provided detailed specification, drawings, and made the sourcing of these threaded inserts painless.”

Ultimately, Bluefin engineers chose Yardley Trisert® stainless steel threaded metal inserts for the application. Trisert® inserts are designed to produce strong threads in plastics, soft metals and wood. They are self-tapping and provide high torque and pull-out resistance.

Ultimately, Bluefin engineers chose Yardley Trisert® stainless steel threaded metal inserts for the application. Trisert® inserts are designed to produce strong threads in plastics, soft metals and wood. They are self-tapping and provide high torque and pull-out resistance.

A metal insert was used instead of a plastic insert to provide greater strength and resistance to stripping of the threads under stress. In addition, 316 stainless steel was chosen for superior corrosion resistance to the harsh sea water environment.

“It’s interesting to work with manufacturers like Bluefin,” said Bailey. “Our metal inserts are helping an AUV perform underwater exploration!”

Yardley Trisert® stainless steel threaded metal inserts are available for purchase online at yarinsertstage.wpengine.com or by contacting Yardley Inserts at 800-457-0154. In addition to stainless steel threaded metal inserts, Yardley Inserts manufactures a full line of standard and custom press-in, molded-in, epoxied-in, self tapping, ultrasonic, and thermal insert fasteners.

About Bluefin Robotics:

Bluefin Robotics manufactures and develops Autonomous Underwater Vehicle (AUV) vehicles, systems, and technology. Founded in 1997, the Company has grown to become a world leader in AUV products designed for military, commercial and scientific applications. Bluefin Robotics is a wholly-owned subsidiary of the Battelle. For more information visit www.bluefinrobotics.com or contact Deanna Abraham at (617) 715-7080 or at dabraham@bluefinrobotics.com.

About Yardley Inserts, Corp.:

Yardley Inserts LLC, is a manufacturer of precision engineered threaded metal inserts for a wide range of fastening applications. Yardley inserts feature designs that “lock” them securely into plastic, metal or wood base materials. Inserts are available for a variety of installation methods including molded-in, pressed-in, threaded-in, thermal, and ultrasonic vibration. Yardley Inserts offers a large inventory of more than 24 million inserts, fast delivery, and provides insert design and custom manufacturing.